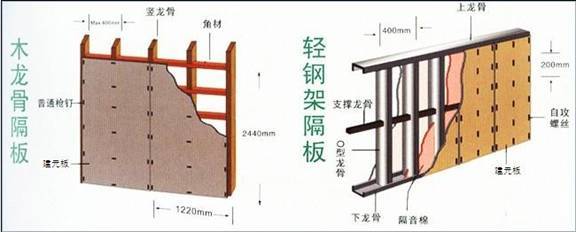

Partition wall installation

Installation method 1、 Light steel keel framework 1. Setting out snap line 2. The keel shall be fixed on the floor and the top floor respectively with shooting nails or expansion screws 3. Arrange the whole keel according to the design requirements (612mm for one ship), and install the cross bracing keel 2、 Plate packaging and fixation 1. First cut the board to the required size (about 10 mm shorter than the wall height) 2. The plate is fixed on the keel with self tapping bee wire in the way of staggered seam. The spacing of self tapping screws is generally about 200-250mm, which needs to be sunk into the plate surface by 0.5mm 3. It should be noted that about 4mm expansion joint should be left between plates. 4. The sealing plate should be fixed from the middle of the plate to the periphery of the plate. It is not allowed to operate at multiple points at the same time, so as to avoid the distortion of the plate due to internal stress 5. Glass wool or rock wool can be placed in the cavity of keel framework as required to enhance the sound insulation and fire prevention effect before the plate is packaged and fixed.

Light steel keel wall is mainly used for internal partition wall. When it is used in the parts with high requirements on sound insulation, fire prevention, waterproof, anti-theft and durability such as household wall, corridor and staircase, the board type and reasonable wall structure should be carefully selected. (please contact our technical support department)

·The continuous length of the wall should not be greater than 25m, and expansion joints can be set if it exceeds.

·The keel and the building structure should be firmly connected. The connection between the frame of the keel and the building structure can be fixed with expansion bolts or shooting nails, and the spacing should not be greater than 800mm. When the through keel is used to strengthen the wall rigidity, the spacing should not be larger than 1500mm. The vertical keel is connected with the horizontal keel with a diameter of 4mm and a length of 8mm, or fixed with a special keel clamp.

·The plate is fixed on the keel with self tapping screws. If not specified, the specification of self tapping screw is generally 3.5 ~ 4mm in diameter and 25 ~ 35mm in length.

·The wall and beam, slab, wall and column shall be firmly connected, and the joint shall be closely connected without gap. Putty or sealing caulking bonding material suitable for the plate shall be used to fill, scrape and paste crack proof band to cover the joint.

·For the wall with high fire resistance requirements, the panel series with high fire resistance performance should be used.

·The wall panel can hang objects below 10kg. When the hanger is fixed on the keel, the hanging capacity can be increased. If it is necessary to hang heavy objects, it is necessary to arrange and add steel (wood) base plates or steel (wood) base plates or angle steel and connecting members to transfer the load to the keel framework to prevent the panel from being damaged.

Installation and fixation of Jianyuan board

General requirements for fixing

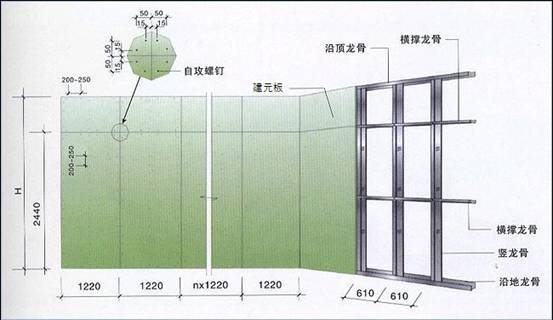

·In general, the Jianyuan board used as partition wall should be laid from bottom to top, with longitudinal arrangement, that is, the long side of the board falls on the vertical keel.

·The plates should be close to each other naturally, and can not be pressed in place.

·If the fire prevention and sound insulation requirements are not too high, the board joints on both sides of the wall can be good, but when the requirements are high, the board joints on both sides of the wall should be staggered, that is, the plate butt joints on both sides of the wall can not fall on the same keel.

·If the height of the wall sealing plate is greater than 3500mm, the vertical joints of the upper and lower plates should also be staggered.

·If the wall sealing plate is double-layer, the joints of the upper and lower plates should also be staggered.

·When arranging the plates at the doors and windows, the plate joints shall not fall on the keel of the door and window frame which is vertical or parallel to the ground surface, so as to avoid the crack of the plate joint caused by the vibration caused by the frequent opening of the doors and windows.

Steps of plate installation and fixation

·Cut plates and openings according to drawings or actual conditions.

The long sides (2440 direction) of the Jianyuan board are generally inverted, while the short side (1220 mm direction) is straight edge. If the original edge is not chamfered due to solid cutting, or when the wall height is 2440 mm, the board edge must be chamfered on site (planed into beveled edge) or directly order the chamfered rice on four sides, so as to better handle the joint.

·Snap the line and mark the fixed point of the plate, and pull out the hole (the hole diameter is 1-2mm larger than the screw head, and the hole depth is 1-2mm), so as to facilitate the wire laying head sinking into the plate surface. The distance between fixed points and plate edge is 5mm, the angle of Ze plate is 50mm, and the spacing between fixed points is 200 ~ 250mm.

·When fixing the guide plate, the plate and keel should be pre drilled (if high-strength self tapping screw is selected, pre drilling is not required), and the hole diameter is 1 mm smaller than that of the glow bolt.

·The Jianyuan board should be fixed with self tapping fly screws. When fixing, it should be fixed from the middle of the board to the periphery, and all screw heads should be sunk into the surface of the board by 1mm

Ocean Willie official public number

Ocean Willie official public number

YUANYANG WEILI

YUANYANG WEILI